The tedious and repetitive process of measuring and assessing track condition and the lack of

generational exchange among the aging skilled expert staff is generating ever-increasing costs for

maintaining rail infrastructure.

The lack of emergence of new revolutionary solutions and decisive

response of infrastructure managers to this problem will cause further aggravation of the problem

and high financial losses in the near time frame.

Challenges

-

Low efficiency of manual measurements

-

High cost of maintenance personnel

-

Lack of automation of the process

-

High cost of diagnostic equipment

Supporting the maintenance processes for railways

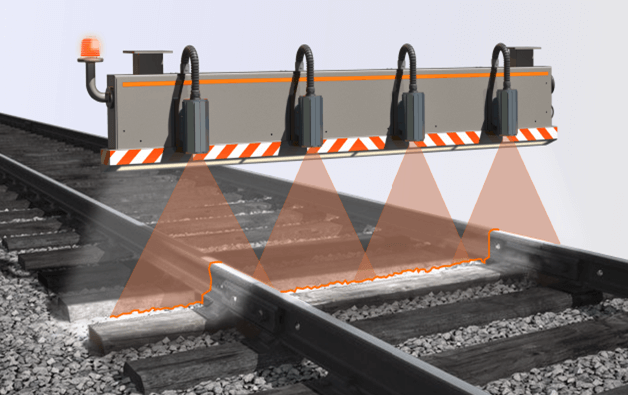

Measurement Automation

Performing track inspections using machine vision instead of manual inspections,

significantly simplifying the planning and execution of rail infrastructure maintenance processes with

less personel engagement.

High inspection efficiency

Measuring up to 400 km of railway tracks per day (depending on the rolling stock used) –

40 times more than with manual inspection in the same time frame.

Low system operating costs

Introducing an unprecedented business model that strongly relieves the customer of the

personnel and monetary expenses associated with acquiring, maintaining, and operating the

system.

Digitization of expertise and data

Unification of expert knowledge while saving and storing the volatile expertise and

replacing it with a digital memory, effecting in remarkably repeatable and reliable defect detection and

evaluation with up to 96% accuracy.

Ease of use

Dedicated streamlined application that allows interaction with the system for AI

prediction refinement and generating digital reports on the condition of rail infrastructure from preset

measurement sections.

Modular design

Easily adaptable to different types of rolling stock and specific needs of the customer,

allowing easy expansion of the system with new functionalities (extension of the analyzed area, creating

digital twins, BIM, etc.).

Service availability

Provide reports from measurements of inspected infrastructure on customer demand in no

more than one business day.

Measured parameters and detected defects

Track condition inspection

- Rails

- Crack

- Chipping

- Head check (HCH)

- Squat

- Fracture

Fastenings

- Missing fastening

- Missing elements (e.g. screw bolt)

Wooden sleepers

- Wide crack

- Signs of wood rot

- Bevelling

- Lack of sleeper (significant degradation)

Concrete sleepers

Ballast

- Completely covered sleeper

- Splashes on ballast

- Ballast level